Homepage > Industrial news > The market prospect of metal silicon powder is good, and the development potential of polysilicon field is the largest driven by photovoltaic industry.

Hits:3025 Createtime:2022-06-29 13:34:56

Metallic silicon powder, also known as industrial silicon powder, is silver gray or dark gray powder with metallic luster. It has high melting point, good heat resistance, high resistivity and high antioxidant effect. It is called "industrial monosodium glutamate" and is an indispensable basic raw material for many high-tech industries.

At present, the mainstream processes of metal silicon powder are Raymond process, impulse spinning process, disk grinding process and counter roll process. Domestic enterprises mainly use horizontal and vertical impulse spinning processes. The future development trend of the product will be more refined and environmental friendly, so the process will develop towards efficiency and environmental protection in the future.

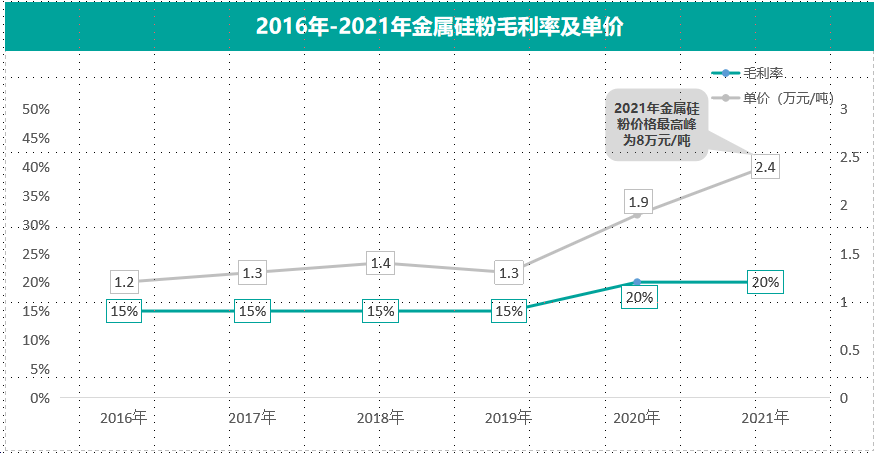

In recent years, affected by the government's environmental protection policies and the industry's resolution of overcapacity and related industries, the price of metal silicon powder has risen, and the market prospect is good.

According to the investigation of research on metal silicon powder industry released by CMRC Zhongyan Century Consulting, the downstream application fields of metal silicon powder mainly include silicone industry, silicon aluminum alloy industry and polycrystalline silicon industry. The price difference of metal silicon powder applicable to the three fields is small, but the demand characteristics are obviously different.

Silicone industry: after purchasing silicon blocks, silicone will be processed into silicon powder according to demand. Domestic silicone enterprises generally purchase according to national standards. Because the industry uses metal silicon powder for chemical reaction, there are requirements for particle size.

Silicon aluminum alloy industry: limited by smelting furnace and smelting process, enterprises have particle size requirements for silicon blocks. Smelting furnaces of different sizes have different requirements. 10mm-100mm is a typical particle size requirement.

Polycrystalline silicon industry: polycrystalline silicon is mainly used in photovoltaic industry and semiconductor materials. Most enterprises usually purchase silicon powder directly from the silicon powder factory, which is responsible for processing industrial silicon blocks into silicon powder. Therefore, the polycrystalline silicon industry has no special requirements for the particle size of industrial silicon. As the photovoltaic industry needs chemical reaction, there are requirements for the particle size. Driven by the rapid development of photovoltaic industry in recent years, polysilicon has the greatest potential in the future.

Online consultation

>Hotline

400-966-0397