Homepage > Industrial news > In the future, the aluminum powder market will gradually reach a balance between supply and demand

Hits:3936 Createtime:2022-07-07 13:06:49

The powder is silver white flake like powder, with excellent hiding power, floatability, opaque to light, reflective to ultraviolet light, radiating heat from sunlight, good weather resistance, excellent corrosion and water resistance. Its performance determines that aluminum powder is widely used in the fields of metallic aluminum pigments, photovoltaic electronic pastes, heat conducting materials and refractories.

Atomization methods include air atomization, inert gas atomization and pressurized water atomization. The upstream raw materials are aluminum ingots. The representative enterprises of this process are Henan ocean Powder Technology Co., Ltd. and Hunan Jintian Aluminum High Tech Co., Ltd. The production safety of the air atomization method is poor. During the production process, the aluminum powder is suspended in the air flow, moving to form a dust fog and associated with static electricity. When the aluminum dust fog reaches a considerable concentration, sparks may cause deflagration, but the production capacity is large, the cost is low, and the equipment is simple. The product produced by nitrogen atomization method is extremely fine ball type, with high activity and high application value, but the product particles are easy to adhere. Pressurized water atomization method has high safety, but the activity of the product is slightly low. At present, the mainstream processes are atomization method and ball milling method. Domestic enterprises mainly use nitrogen atomization method to form spherical aluminum powder. Atomized aluminum powder is widely used, among which micro spherical aluminum powder is the mainstream product in the current market and the upstream raw material of metal aluminum pigment and photovoltaic electronic paste industry.

Ball milling method includes "dry method" and "wet method", and the upstream raw materials are aluminum ingots or atomized aluminum powder. The representative enterprises of this process are Angang industrial micro aluminum powder Co., Ltd. and Hebei Jisheng aluminum powder Co., Ltd. The "dry method" ball milling method has the advantages of simple process, low cost, large output, high production efficiency and high safety, which can avoid environmental pollution, but the fluidity of flake powder is poor. The "wet" ball milling method has less auxiliary equipment, simple equipment, low noise, fine and uniform grinding particle size, and less pollution to the working environment.

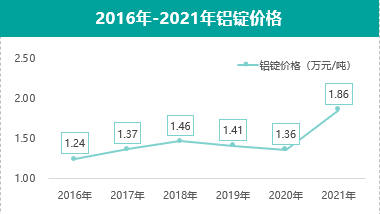

The unit price of aluminum powder is directly related to its upstream raw material aluminum ingot. The mainstream pricing method of aluminum powder unit price is aluminum ingot benchmark price + processing fee. From 2016 to 2020, the unit price of aluminum powder was relatively stable, and after 2020, the unit price increased significantly. Due to the wide price range of aluminum powder of various specifications, the price of high-purity atomized spherical aluminum powder is about 120000 yuan / ton, and the price of flake aluminum powder is 19800 yuan / ton

Trend chart of aluminum ingot price from 2016 to 2021

At present, there are about 20-30 domestic aluminum powder manufacturers, and the leading enterprises are Angang industrial micro aluminum powder Co., Ltd. and Henan ocean Powder Technology Co., Ltd. According to the "aluminum powder industry research" report released by CMRC, the national aluminum powder output can reach 160000 tons in 2021. At present, the market supply exceeds demand. In the next three years, the aluminum powder market scale will grow slowly and gradually reach the state of supply and demand balance.

Online consultation

>Hotline

400-966-0397