Homepage > Industrial news > China's power battery recycling track is plagued with pain points, or can learn from overseas mature recycling experience.

Hits:3210 Createtime:2024-02-05 14:08:32

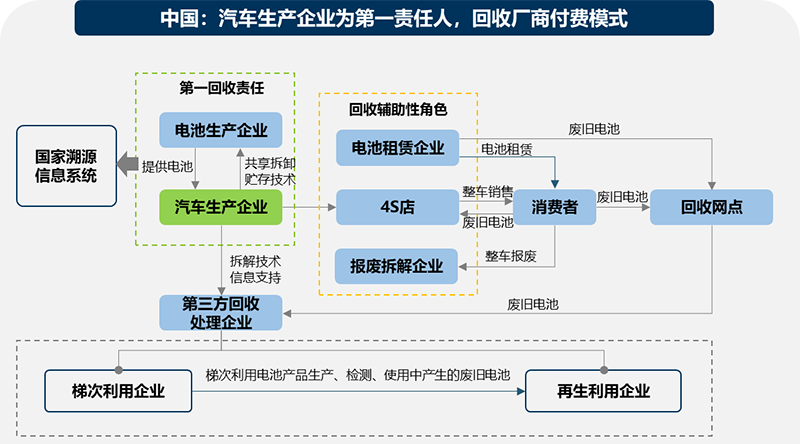

China's new energy vehicle sales continue to grow, followed by the Chinese market is facing a large number of used power batteries need to be recycled. China's recycling market according to the "Interim Measures for the Management of the Comprehensive Utilization of Used power batteries for New Energy Vehicles", automobile manufacturers are responsible for establishing recycling channels to recycle retired lithium batteries for power vehicles. At the same time, automobile manufacturers, battery manufacturers and third-party recycling enterprises are encouraged to cooperate to build a power battery recycling system.

Figure 1 Standard model of China's power battery recycling market

According to China's standard model of power battery recycling, Oems and battery factories bear the responsibility of recycling batteries, Oems should establish traceability systems and recycling outlets, provide owners with buyback, old for new, subsidies and other incentives, timely sharing of battery disassembly and storage technology, recycling outlets and other information; The product structure design of the battery factory should be standardized and easy to disassemble, the battery coding management should be carried out, and the recycling related information such as the disassembly and storage technology of the collaborative pool with the automobile production enterprise and the recycling network should be strengthened, and the battery information should be upload to the traceability information system established by the state. Step utilization and recycling enterprises (third parties) in order to assume the key role of comprehensive utilization of recycling back-end batteries, the vehicle manufacturer provides the support of dismantling technical information; New energy vehicle 4S shops, battery leasing and other operating enterprises assume the auxiliary role of recycling, verify the information of the owner of the new energy vehicle when the battery is repaired, dismantled and replaced, and transfer the used batteries to the recycling network, and shall not be transferred to other units and individuals. In general, battery factories and comprehensive utilization enterprises need to cooperate in recycling, and can be tested before treatment.

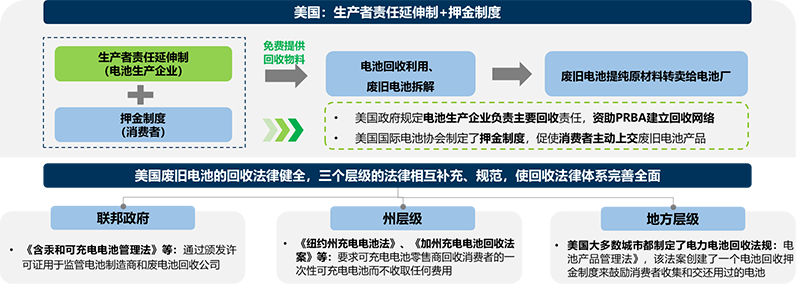

Us power battery recycling standard (current) model:

The United States is dominated by market regulation, and the government conducts restrictive management of battery recycling through a three-level legal system, forcing battery retailers to recycle batteries free of charge, and making a deposit system by BCI to encourage consumers to take the initiative to hand in used batteries. At the same time, the battery manufacturers funded the American Portable Rechargeable Battery Association (PRBA) to establish a recycling network and educate the public about battery recycling knowledge, and guide the public to actively cooperate with the recycling work.

Figure 2. U.S. Power battery recycling standard (current) model

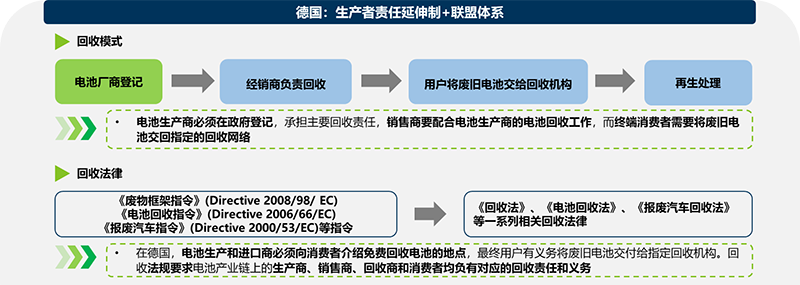

German power battery recycling standard (current) model:

The German government legislates recycling, the producers bear the main responsibility, and set up funds to improve the market-oriented construction of the recycling system. Under the constraints of the relevant legal framework, the waste battery recycling system in Germany has a clear division of labor, and producers, consumers and recyclers in the industry chain have corresponding responsibilities and obligations. The integration of responsibility, obligation and law has made remarkable achievements in battery recycling in Germany.

Figure 3. German power battery recycling standard (current) model

Japan power battery recycling standard (current) mode:

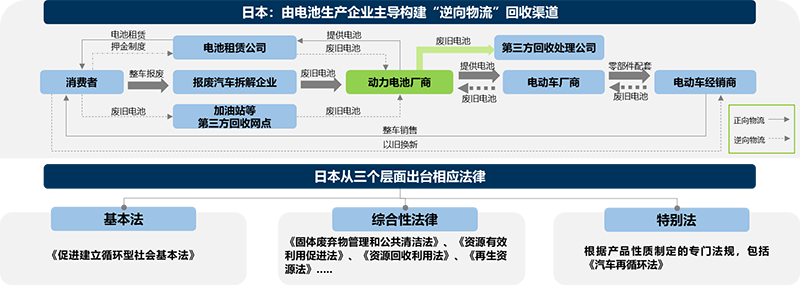

Affected by the shortage of raw materials, Japan is a global leader in the recycling of used batteries. At present, Japan has established a recycling channel mainly dominated by battery companies and with the idea of "reverse logistics". Because the Japanese people have a strong sense of identification with garbage classification and recycling, they can use the service network of retailers, car dealers or gas stations to recycle used batteries for free to consumers, and the recycling route is opposite to the sales route. In order to regulate the development of the industry, Japan has introduced corresponding laws from the three levels of the Basic law, the comprehensive law and the special law to support technical research, and give corresponding subsidies to production enterprises to improve the enthusiasm of recycling.

Figure 4: Japan's power battery recycling standard (current) model

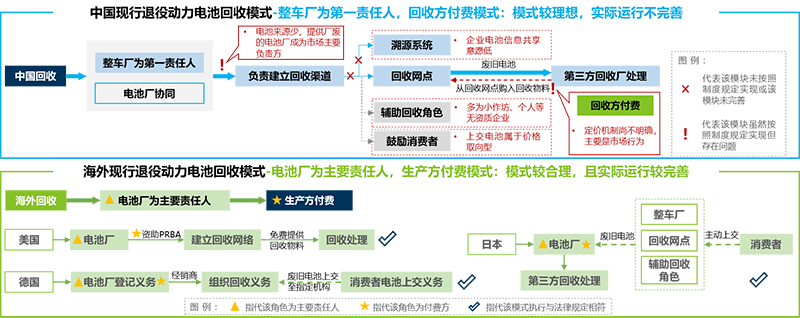

Comparison of decommissioned power battery recycling modes in China (current) and overseas:

The biggest difference between domestic and foreign recycling models is that in China's recycling market, the vehicle factory is the first responsible person and the recycling plant pays the model, while in the overseas recycling market, the battery factory is the main responsible person and the manufacturer pays the model. From the perspective of implementation, the recycling channels established by Oems in the Chinese market are not perfect, and the recycling mode in overseas markets is more mature and runs well.

Figure 5 Comparison of recycling modes of decommissioned power batteries between China and foreign countries

China decommissioned power battery recycling market pain points:

Unqualified enterprises disrupt the recycling market, retired lithium battery effective recovery rate is low: the biggest problem in the current power battery recycling market is that the recycling channel is not perfect; The pricing mechanism is not clear, the recycling role is mostly small workshops, individuals and other unqualified enterprises, the market power battery scrap amount is significantly higher than the effective recovery amount;

Profit margin Low cost battery recycling profit constraints:

(1) The current decommissioned lithium battery recycling business has factors such as manpower, technology, equipment, and lack of input credits, resulting in high overall costs, and most formal recycling entities lack the power to recycle decommissioned batteries;

② The economic benefits of different batteries are different, and the recycling price of ternary lithium batteries can reach several times that of lithium iron phosphate batteries, and at present, retired batteries on the market are mainly lithium iron phosphate batteries. To improve profitability in the future, enterprises, industrial alliances and governments need to work together.

With reference to overseas mature development experience, China's recycling market can learn from relevant experience to deal with the pain points of the recycling market:

1) Referring to the development experience of European and American countries, the implementation of the extended producer responsibility system is the primary task of the industry to achieve standardization, only by making clear the recycling responsibilities and obligations of each link, the industry can get rid of disorderly competition and enter the stage of sound development. Although China has initially established a power battery recycling policy framework system with extended producer responsibility as the basic principle, due to low legal level, lack of enforcement and the corresponding reward and punishment system, the actual implementation effect is not ideal;

2) At present, China has initially completed the full life cycle regulatory coverage of power batteries, and the industry chaos rectification is already on the line. In the Interim Regulations on the Traceability Management of New Energy Vehicle Power Battery Recycling and Utilization issued by the Ministry of Industry and Information Technology in July 2018, it is clearly proposed to establish a "new energy vehicle national monitoring and comprehensive management platform for power battery recycling and traceability", which requires information collection in the whole process of power battery production, sales, use, scrap, recycling and utilization. To monitor the performance of the recycling responsibility of each link;

3) China should explore the profitability of decommissioned lithium battery recycling market from three aspects:

① Enterprise side: the production side should strive to establish recycling channels and improve the recycling network. Recycling enterprises should pay attention to the advanced nature of recycling technology and reduce costs from the technical side;

② Industrial alliance: each market player forms an industrial alliance to achieve information sharing and form economies of scale;

③ Government side: strengthen policy subsidies and recycling channel supervision.

Online consultation

>Hotline

400-966-0397