Homepage > CMRC understandings > 【CMRC】With frequent energy storage accidents at home and abroad, how can domestic temperature control enterprises seize the tens of billions of energy temperature control market?

Hits:2000 Createtime:2024-03-27 17:16:09

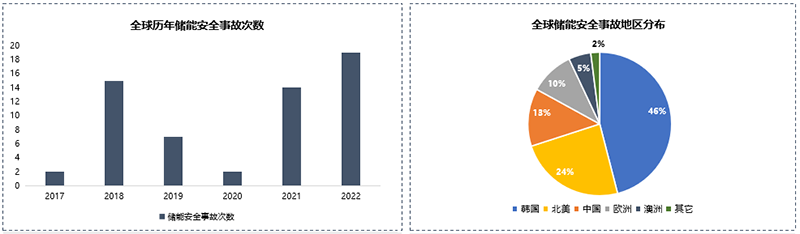

South Korea is a high incidence of energy storage safety accidents, accounting for 46%, the main reason is that South Korea's energy storage installation application of terene lithium batteries (high temperature conditions are explosive), China, North America and other rapidly developing regions initiated a number of accidents. Japan has the fewest energy storage safety accidents, with only one accident by 2022.

Figure 1 Number of safety incidents and accident regions in 2017-2022 globally

The thermal runaway of lithium battery is the main reason that affects the safe operation of energy storage power station. Thermal runaway refers to the phenomenon that when the lithium battery encounters mechanical abuse, electrical abuse and thermal abuse, the battery material is damaged and abnormal heat is generated, and the heat continues to accumulate and eventually cause the internal temperature rise of the battery to be uncontrollable. According to our incomplete statistics, most energy storage safety accidents occur during or after charging, when the battery voltage is high, the battery activity is large, and the circulation between the parallel battery clusters is formed, resulting in the cell being overcharged and the voltage rising to form an internal short circuit, so it is easy to cause fire accidents.

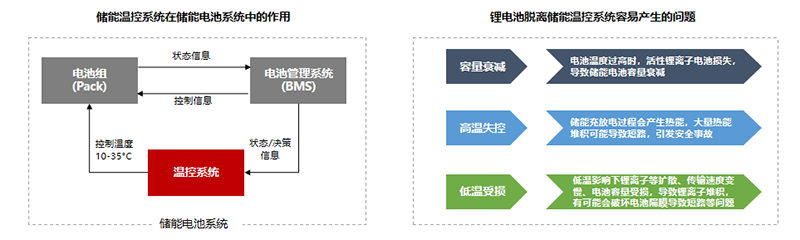

The role of energy storage temperature control equipment is to keep the temperature of energy storage battery equipment in a reasonable range, which is a key part of the security of energy storage system:

The energy storage temperature control system provides thermal management services for the energy storage battery. By receiving the battery control information (temperature, voltage, current and other parameters) provided by the BMS, the temperature control management decision information is provided to maintain the battery operating temperature within a reasonable range (10-35°C) and realize the stable operation of the energy storage battery system.

Energy storage temperature control is indispensable in the energy storage system. If the temperature is not properly controlled, too high or too low temperature stimulation may cause capacity and life attenuation, and in serious cases, it may lead to short circuit and cause safety accidents.

Figure 2 The role of the energy storage temperature control system in the energy storage system

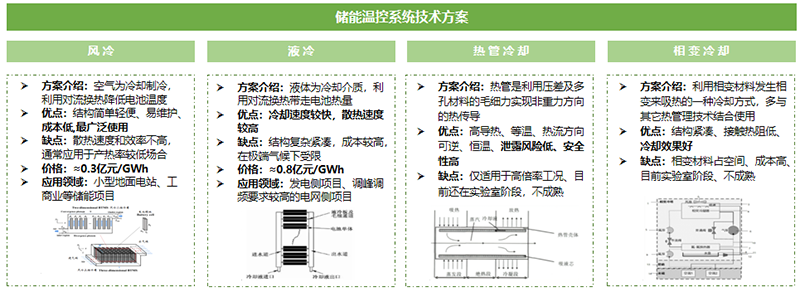

At present, the technical route of energy storage temperature control system can be divided into four categories: air cooling (air cooling), liquid cooling, heat pipe cooling, and phase change cooling:

At present, the air cooling scheme is more mature, and occupies the mainstream position with low investment cost, simple structure and easy installation; Compared with air cooling, the liquid cooling scheme has higher cooling efficiency and better heat dissipation effect, but the technical difficulty is greater and the cost is higher. Heat pipe and phase change cooling have not yet been industrialized, are still in the laboratory stage, and are not mature enough.

FIG. 3 Technical scheme of energy storage temperature control system

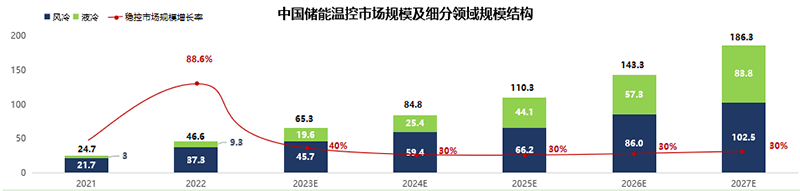

In 2022, the overall scale of China's energy storage temperature control market will be 4.66 billion yuan, an increase of 88.6% compared with 2021. Experts conservatively expect that by 2027, China's energy storage temperature control market will reach 18.63 billion yuan, and experts conservatively estimate that the compound annual growth rate will exceed 30%, which is basically consistent with the growth rate of energy storage system installed capacity.

With the continuous improvement of the scale of energy storage projects, the refrigeration efficiency of air cooling may not be able to meet the heat dissipation needs of some projects, when the demand for liquid cooling with higher refrigeration efficiency is expected to increase, experts expect that by 2027, the liquid cooling market size will exceed 8 billion, the market share will reach 45%. However, projects with small heat output are enough to meet the heat dissipation needs, such as small ground power stations, industrial and commercial, communication base stations and other energy storage projects. In the long run, although the proportion of liquid cooling will increase, the two technologies will still have their application scenarios.

Figure 4 Scale of China's energy storage temperature control market and scale structure of subdivisions

Domestic temperature control enterprises need to overcome the air cooling & liquid cooling technology threshold, channel resource threshold, supplier qualification threshold and customized design threshold to seize the 10 billion energy storage temperature control market:

Temperature control system is an important guarantee for the safe and efficient operation of energy storage projects, so it has relatively strict requirements in terms of control accuracy and operation reliability. For example, compared with ordinary civil air conditioners, precision air conditioners used in air cooling systems need to be upgraded in terms of air circulation, heat dissipation efficiency, stability, service life, and reliability. For the liquid cooling scheme, how to ensure the heat dissipation effect while avoiding the leakage of coolant also has greater technical difficulty. Therefore, it is not easy to cross the border into the field of energy storage temperature control, and there are certain technical barriers in the industry.

The energy storage temperature control system is highly customized and requires sufficient project experience. Energy storage is widely used in power systems, and different scenarios often have different requirements for energy storage systems, even for similar application scenarios, the technical solutions of different energy storage system integrators may also be different. Therefore, the energy storage temperature control system is not a standardized product, but usually needs to be customized for the specific requirements of different projects or different manufacturers' technical solutions. It is difficult for new enterprises without temperature control experience.

The qualification certification of energy storage temperature control equipment suppliers generally includes three steps: the first step is the supplier background certification, auditing the company's technology, management, and supply chain; The second step for product quality certification, prototype product trial production; The third step is the supply certification of small batches, and the overall certification cycle can reach 10-12 months. Take liquid cooling products as an example, before leaving the factory, it is necessary to carry out multi-directional testing on the appearance size of the liquid cooling plate, pressure bearing resistance, sealing, corrosion resistance and other indicators, and the factory testing from small batch samples to large batches of supply is many and time-consuming, and the certification cycle can be up to 12 months. The qualification threshold is a huge challenge for new entrants.

Energy storage system integrators have the main right to choose temperature control system suppliers. In the bidding process of the domestic energy storage system, the owner often only decides the EPC manufacturer, the energy storage system integrator, and some owners will specify the specific cell supplier, but the choice of other parts is often decided by the EPC manufacturer and the energy storage system integrator. Therefore, how to open up downstream sales channels will be a big difficulty for new enterprises.