Homepage > Industrial news > Benefiting from the upsurge of wafer factory expansion and the long-term domestic substitution dividend, the domestic semiconductor industry has a bright future.

Hits:2506 Createtime:2022-08-12 13:23:25

In order to achieve the important strategic goal of high-quality development in China, the semiconductor industry needs to solve the "bottleneck" problem from the source. The localization and replacement of related equipment and materials in the industrial chain will be the main trend in the future. From the perspective of the international situation, the Sino US trade friction continues, the mismatch between supply and demand accelerates the transfer and expansion of wafer factories to the mainland, and domestic manufacturers will usher in a good opportunity for development. With the support of national policies, China's semiconductor industry is currently in a boom period:

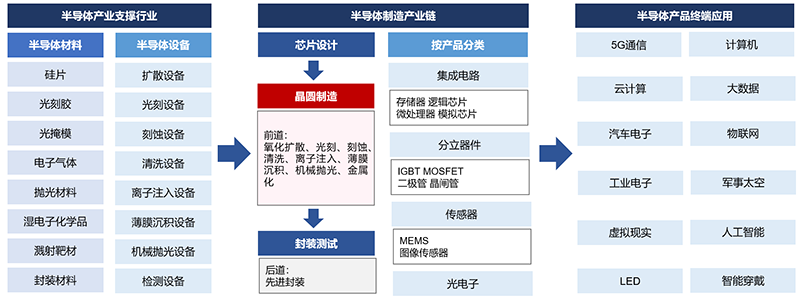

According to CMRC research, the semiconductor industry chain can be divided into upstream semiconductor support industry, midstream semiconductor manufacturing industry and downstream semiconductor application industry. The upstream semiconductor support industry provides raw materials and production equipment for semiconductor manufacturing; The midstream semiconductor manufacturing industry mainly includes chip design, wafer manufacturing and packaging testing industries; Downstream semiconductor product terminals are widely used in consumer electronics, industrial electronics, automotive electronics, communication technology, big data, cloud computing, artificial intelligence, Internet of things, medical care, new energy and other fields.

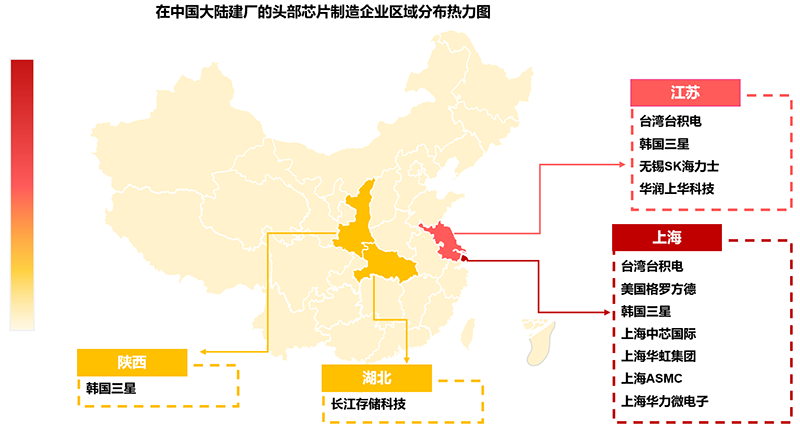

The chip production process will involve dozens of special semiconductor equipment and hundreds of semiconductor materials. Semiconductor equipment and materials are the underlying cornerstone supporting the steady development of the semiconductor industry. At present, international and domestic semiconductor manufacturing enterprises with factories in China are concentrated in southeast coastal cities such as Shanghai and Jiangsu, and the industry concentration is obvious

The market of semiconductor equipment and materials is mainly occupied by overseas, and there is huge room for domestic substitution. The top ten companies in the semiconductor equipment market account for about 80% of the global semiconductor market, and the representative manufacturers are mainly applied materials, asmall, Fanlin semiconductor, Tokyo electronics, etc; There are many segments in the semiconductor material market. Compared with the equipment market, the competition pattern of the segment market is slightly scattered. The average concentration of the leading companies is 60% - 70%, which is still dominated by overseas companies.

Domestic semiconductor equipment manufacturers have made layout in each sub semiconductor equipment field and developed rapidly. They are expected to benefit from the expansion boom of wafer factories and the long-term domestic substitution dividend. At present, the domestic semiconductor equipment manufacturers account for less than 10% of the global semiconductor equipment supply, and the localization rate is less than 20%. It is expected to benefit from the expansion boom of the wafer factory, continue to obtain verification and import opportunities and equipment orders, constantly improve market share and achieve high performance growth.

Online consultation

>Hotline

400-966-0397